Leb-Tile Delux ceiling panels are heat insulating products used in the cladding of houses, hotels and other structures, where the aesthetic and architectural effect of a tiled roof is required.

In addition, they offer a ready-made, completely ecological roof, inside the buildings where they are applied.

Leb-Tile Delux ceiling panels have 12mm natural timber battens embedded in the bottom.

They can thus be used in visible constructions as such, without requiring for aesthetic reasons to cover them with false ceilings.

Advantages:

1. Light Weight.

2. Speed.

3. Economy.

4. Thermal insulation.

5. Soundproofing .

6. Watertightness.

7. Resistance to time and pressure.

8. Application from small slopes, 15% and above.

9. Significant aesthetic and ecological advantage.

POLYURETHANE

Odorless foam that prevents the growth of mold and fungi, remains chemically neutral, and moisture does not alter its mechanical properties. It is sensitive in texture to prolonged sunlight exposure and contact with water only on the exposed surface.

For the expansion of the foam, Pentane is used, which is ozone-friendly and environmentally safe as it does not contain chlorofluorocarbons (CFC & HCFC Free.)

Density: 40±2 Kg/m3 (ISO 854/DIN EN 1602)

Thermal Conductivity (at 10°C): λ=0.0233 W/mk or λ=0.0200 Kcal/mh°C or u=0.32 W/m2K (EN ISO 7345)

Compression Strength: 187 Kpa or 18.7 ton/m2 (ISO 844/DIN EN 826)

Adhesion: 125 Kpa or 12.5 ton/m2 (ASTM D 162/ DIN EN 1607)

Percentage of closed cells: 95-98% (ASTM D 285)

Dimensional stability: 1% (ISO 2796/DIN 5343/EN 1604)

SHEET METALS

Painted sheets of quality S220GD/S250GD/S280GD or DX51D

Galvanized or aluzinc base, with a polyester coating of 25 microns exterior and 7 microns interior, in accordance with EN10143 and EN 10346.

Upon request, laminated/antibacterial sheets can also be used.

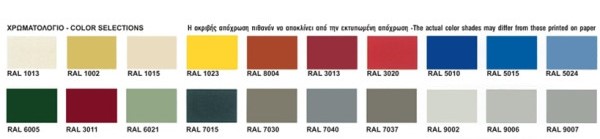

COLORS

An exceptionally wide range of coating color options is available.

Please inquire about available colors (RAL 8004, RAL 6005, RAL 1002, RAL 7015)

| Thermal Transmittance Coefficient ** | 0.32 W/m2K |

| Panel Length [mm] | Panel Weight [kg]* |

| 1.75 | 24.50 |

| 2.07 | 28.98 |

| 2.39 | 33.46 |

| 2.71 | 37.94 |

| 3.03 | 42.42 |

| 3.35 | 46.90 |

| 3.67 | 51.38 |

| 3.99 | 55.86 |

| 4.31 | 60.34 |

| 4.63 | 64.82 |

| 4.95 | 69.30 |

| 5.27 | 73.78 |

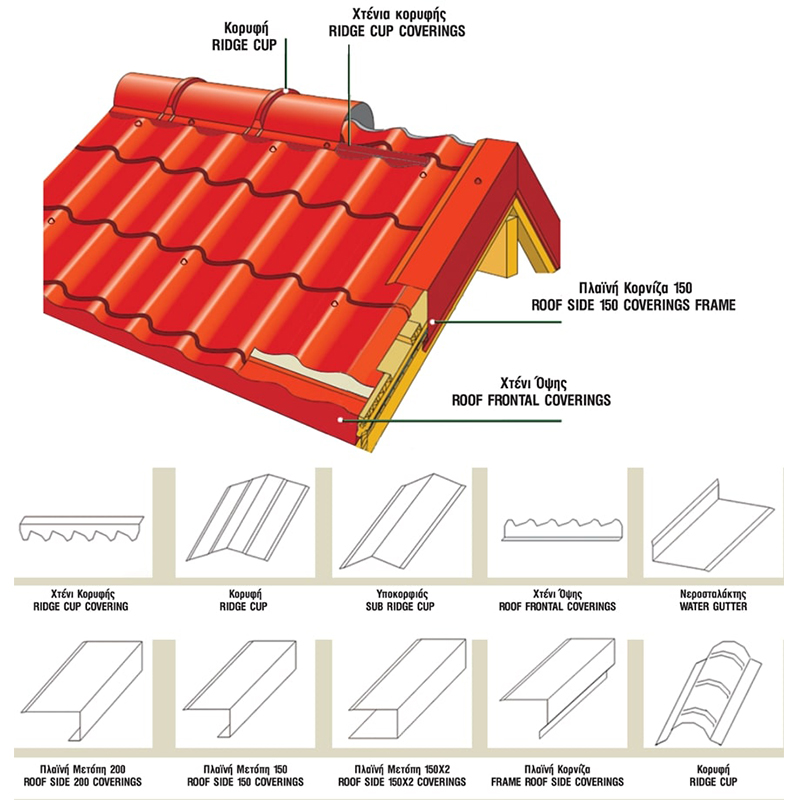

INSTALLATION INSTRUCTIONS

The technical installation of our wooden panels differs from that of common metal panels. While in metal panels the primary support beams (metal or wooden) are placed perpendicular to the length of the panels, in the wooden tile panel, the primary support beams are placed parallel to their length at a distance of one (1) meter, which is also the length of the panels, that is, underneath the joint of two adjacent panels. This way, we achieve an increase in mechanical resistance across the width, over 500 kg/m², while also eliminating the asymmetry of the joints. The presence of a small deviation from the parallelism of the rabbet on either side of the beam is due to the existence of the necessary joints that contribute to the stability of the final structure.

The dimensions of the contact wooden beams depend on the existing loads in the area (snow, wind), the length, and the weight of the panels, which is 14 kg/m². Since the wooden beams have a limited length (from 2 to 6 meters), it is clear that vertical second support beams will be needed at both ends. The thickness and height of the ready-made first and second contact beams are calculated based on the above factors and can be simple wooden beams or laminated or glulam beams, as commonly known in the market, but also metal beams depending on the requirements of each construction.

In any case, components are available whose use is necessary for the complete waterproofing of the roof and the protection of the natural wood.