The use of common panels in livestock units presents significant problems. Animal fumes cause corrosion of the internal metal surfaces of common panels, thereby minimizing their lifespan. Our company's polyester panel, LEB-FARM, is ideal for use in large livestock and poultry farms. The inner surface with polyester provides enormous lifespan to the panels and makes them the best choice for such spaces.

However, the advantages of LEB-FARM over other panels that are proposed as a solution for this specific use are also important. The mechanical strengths of polyester are significantly high - due to its fiber reinforcement. Also, the contraction - expansion of the material is minimized. For this reason, LEB-FARM does not show cracks (breakage) after a few years. Polyester also presents significant advantages in case of fire. Plastic materials in case of fire produce droplets that fall from the roof to the ground and help spread the fire. Polyester does not create these kinds of drops, so it does not contribute in any way to the spread of fire.

POLYURETHANE

Odorless foam that prevents the growth of mold and fungi, remains chemically neutral, and moisture does not alter its mechanical properties. It is sensitive in texture to prolonged sunlight exposure and contact with water only on the exposed surface.

For the expansion of the foam, Pentane is used, which is ozone-friendly and environmentally safe as it does not contain chlorofluorocarbons (CFC & HCFC Free.)

Density: 40±2 kg/m3 (EN 13165)

Percentage of closed cells: 95-98%

Class: B3 according to DIN 4102. Upon request, B2 or PIR foam can also be produced.

Dimensional stability: ±2%

POLYESTERS

Composite sheets of unsaturated polyester resin with a styrene base, reinforced with fiberglass, polymerized through a continuous and irreversible high-temperature production process.

General Characteristics

| Nylon threads distance |

10mm ca |

|

| Resin |

~70% ca |

internal test |

| Fiberglass reinforcement |

~30% ca |

internal test |

| Specific weight |

~1.460 g/cm3 | internal test |

| Operating temperature range |

-40 C : +120°C |

|

| Heat transfer coefficient |

0.15 W/m°K |

EN 12667:2001 |

| Tensile strength |

123.6 N/mm2 |

ASTM D-638 |

| Compressive strength |

129.4 N/mm2 |

ASTM D-695 |

| Bending strength |

185 N/mm2 |

UNI EN 1013-2 |

| Bending modulus |

~6000 N/mm2 |

UNI EN ISO 178:2006 |

| Thermal linear |

||

| Coefficient of expansion |

3.2 X 10-5 °C-1 |

ASTM D-696 |

SHEET METALS

Painted sheets of quality S220GD/S250GD/S280GD or DX51D.

Galvanized or aluzinc base, with a polyester coating of 25 microns exterior and 7 microns interior, according to EN 10143 and EN 10346.

Upon request, laminated/antibacterial sheets can also be used.

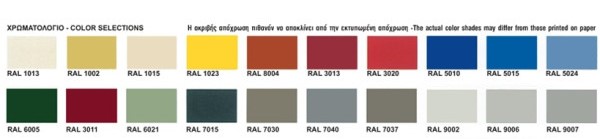

COLORS

An exceptionally wide range of coating color options is available.

Please inquire about available colors.

Each project is unique and has its own specifications and requirements.

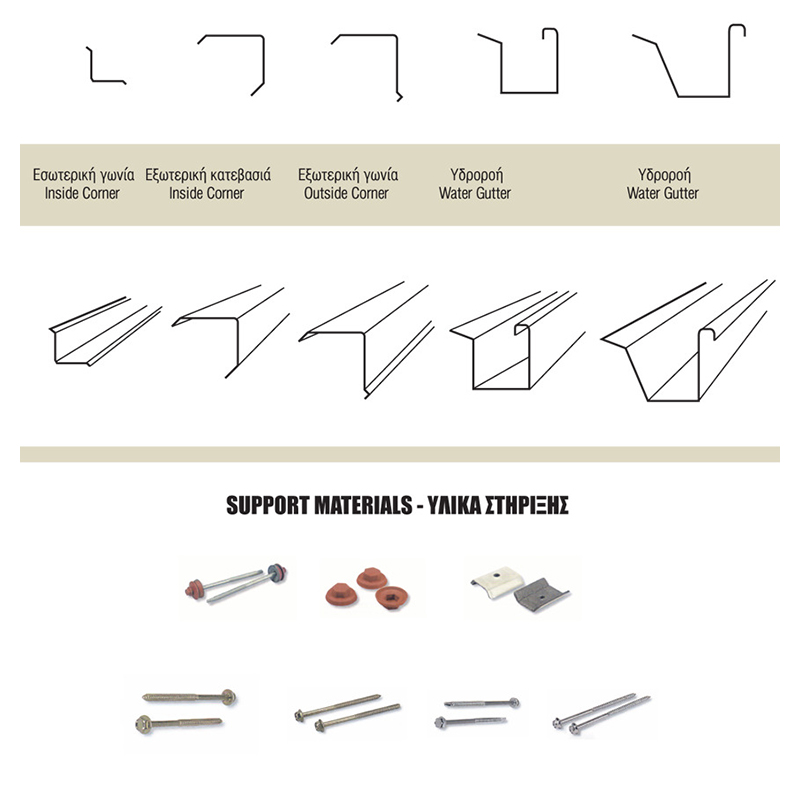

Our company offers a complete range of ready-made components and connection materials.

In any case, there is also the possibility of designing components upon request.