Leb-Freeze thermal insulation panels for cold rooms are composite panels, consisting of two lightly formed, galvanized and pre-painted metal sheets and an insulating structural core of hard polyurethane foam.

In particular, the heat-insulating panels for cold rooms/chambers are:

1) Used in temperature-controlled areas.

2) Used for the construction of areas for the preparation, storage, preservation and freezing of food and other perishable products.

3) Produced with non-burdensome materials, fully complying with the applicable European Standards regarding hygiene and food protection.

POLYURETHANE

Odorless foam that prevents the growth of mold and fungi, remains chemically neutral, and moisture does not alter its mechanical properties. It is sensitive in texture to prolonged sunlight exposure and contact with water only on the exposed surface.

For the expansion of the foam, Pentane is used, which is ozone-friendly and environmentally safe as it does not contain chlorofluorocarbons (CFC & HCFC Free.)

Density: 40± 2 kgr/m3 (EN13165)

Closed cell percentage: 95-98%

Class: B3 according to DIN 4102. B2 or PIR foam can be produced upon request.

Dimensional stability: ±2%

SHEET METALS

Painted sheets of quality S220GD/S250GD/S280GD or DX51D

Galvanized or aluzinc base, with a polyester coating of 25 microns exterior and 7 microns interior, in accordance with EN10143 and EN 10346.

Upon request, laminated/antibacterial sheets can also be used.

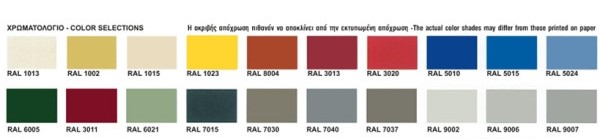

COLORS

An exceptionally wide range of coating color options is available.

Please inquire about available colors

| Nominal Thickness | Panel Weight* | Thermal Conductivity Coefficient |

| [mm] | [kg/m2] | [kcal/m2h°C] |

| 80 | 11.66 |

0.22 |

| 100 | 12.46 |

0.18 |

| 120 | 13.26 |

0.15 |

| 150 | 14.46 |

0.12 |

| 180 | 15.66 |

0.10 |

| 200 | 16.46 |

0.09 |

* The panel weight is calculated considering the core density of 40kg/m3 and the nominal thickness of the sheets 0.50mm / 0.50mm.

** The thermal transmittance coefficient is calculated considering the core density of 40kg/m3, the thermal conductivity coefficient of the core 0.023 W/mK, and the nominal thickness of the sheets 0.50mm / 0.50mm.

The polyurethane wall panels are available with two types of support: visible support (VS) and hidden support (HS). Both in visible and hidden support, the panels can be installed either vertically or horizontally. The special joint design of the LEB-WALL panels, combined with the use of sealing materials, minimizes the joints between panels, achieving:

• Reduction of thermal bridges to a minimum

• Limitation of air and moisture penetration

• Minimization of installation time

• Limited use of additional accessories

The LEB-WALL (FREEZE) polyurethane wall panels with visible support are anchored to the supporting structure using the standard method of visible anchoring. This method provides robustness to the construction, enhancing the industrial appearance of the building.

Each project is unique and has its own specifications and requirements.

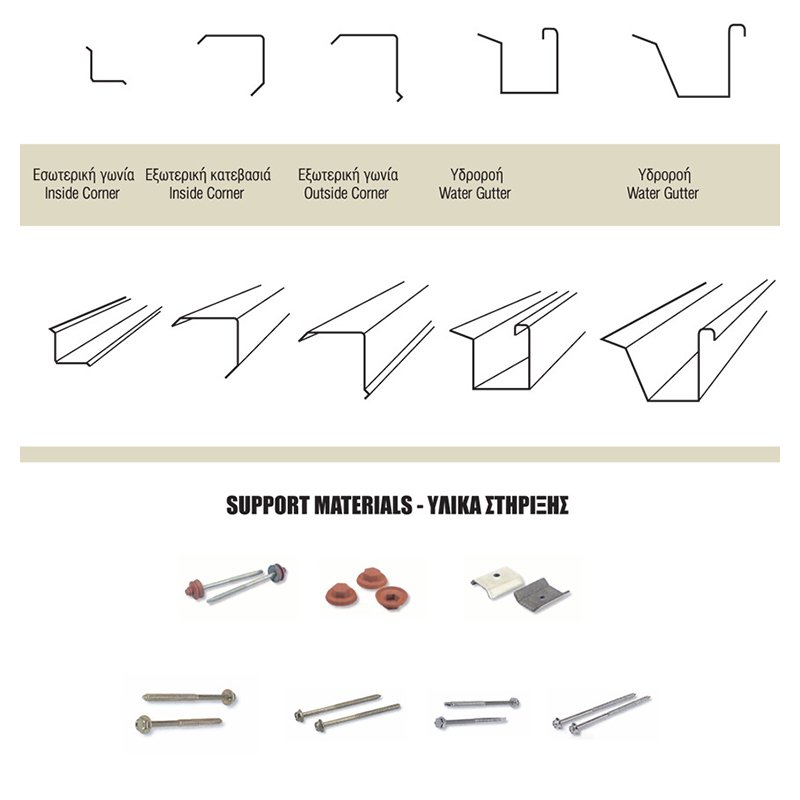

Our company offers a complete range of ready-made components and connection materials.

In any case, there is also the possibility of designing components upon request.